DEVICE DETAILS

The creaming function requires the dismantling of the cooling device and ventilation channels and switching the switch to creaming mode.

The honey decrystallization function requires the dismantling of the mixer, the cooling device, and ventilation channels, and switching the switch to decrystallization mode.

The settling tank function requires the dismantling of the mixer and the cooling device and ventilation channels, and turning off the device.

The device has been submitted for patent protection at the Patent Office of the Republic of Poland.

There is a possibility to deliver the device to the customer via courier service; however, this requires adding an additional amount resulting from packaging and freight costs. We encourage personal pickup. However, if you do not have this possibility, please contact us at the phone number at the bottom of the page or via the contact form on the homepage. We will surely agree on a convenient form of transport.

GALLERY

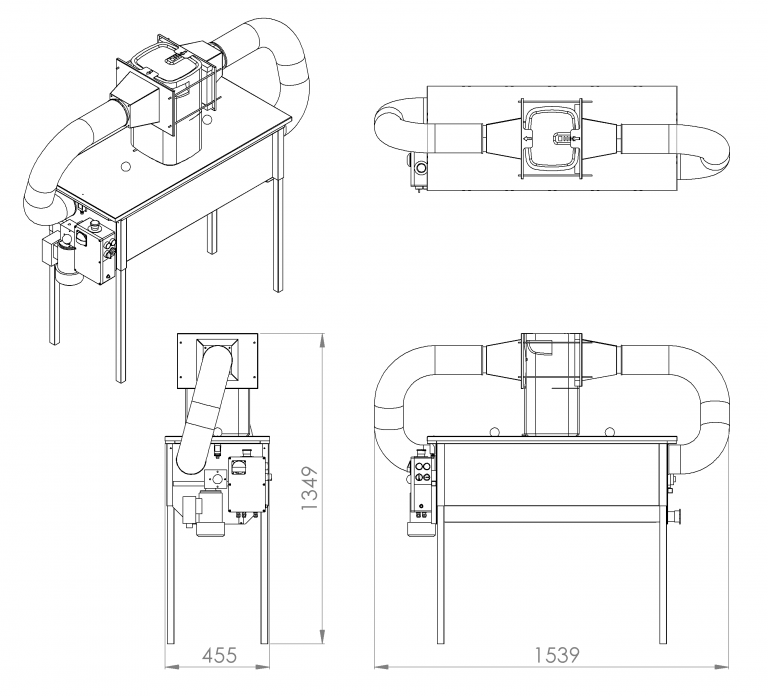

SIZE

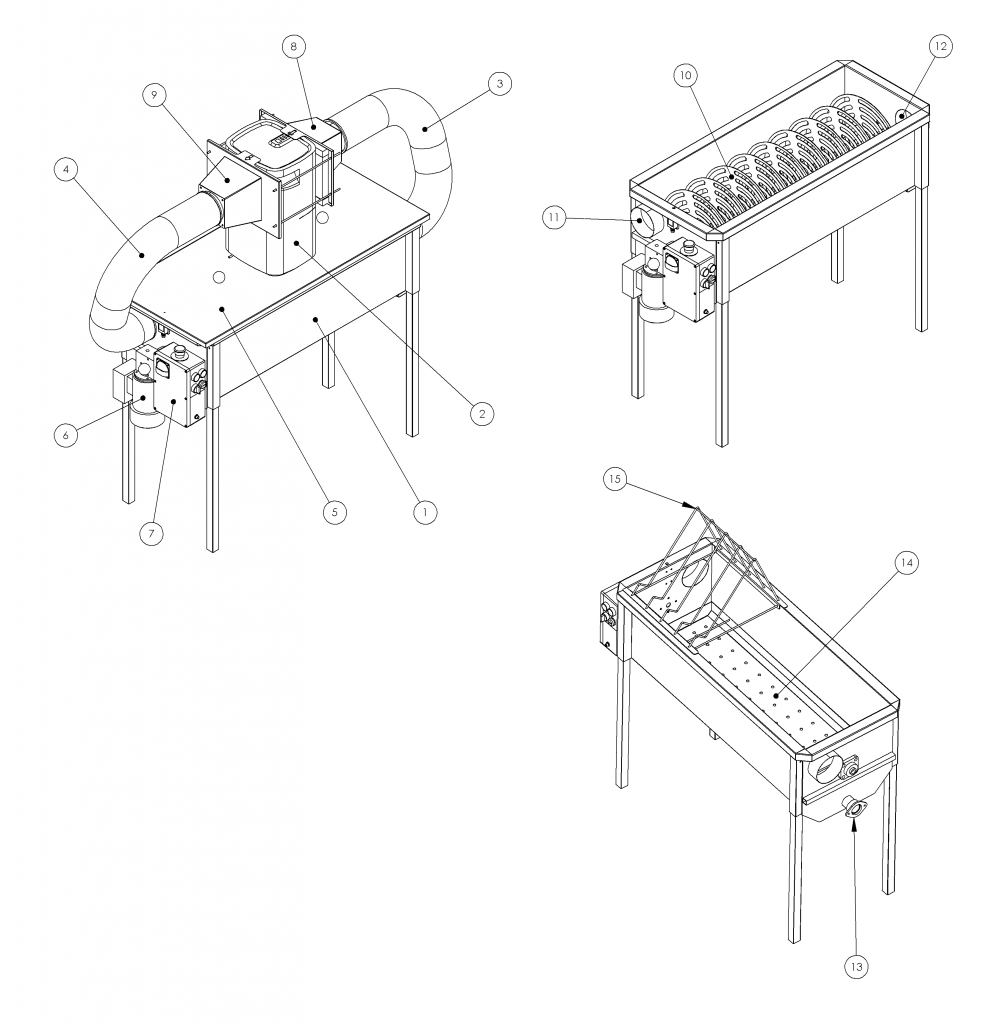

COMPONENTS

- uncapping table made of acid-resistant steel

- air dryer

- flexible moist air hose

- flexible dry air hose

- stainless steel cover

- gearmotor

- control system

- moist air intake

- dry air outlet

- mixer with plates

- dry air inlet

- moist air outlet

- honey drain

- uncapping sieve

- frame stand

The device is safe for honey and does not deteriorate its properties.